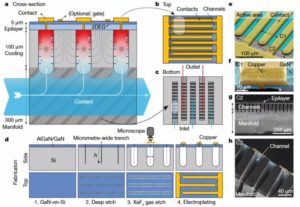

Researchers from the Swiss research university EPFL in Lausanne have demonstrated a new way of water cooling chips, where the coolant flows through the chip ( on-chip liquid cooling ). In the case of conventional water cooling, it is still necessary to ensure adequate heat transfer from the place of origin (ie in the chip) to its surface so that the coolant can collect it there. Such systems are not only cumbersome, but also have limitations on how much heat they can dissipate. These limitations are one of the reasons that the frequency of the chips has more or less stopped (but this is not the main reason), and it also limits the number of cores and further miniaturization (again, not the only reason).

However, if appropriate channels are inserted into the chip during production, through which the coolant is pumped, the heat is captured and dissipated closer to the place of origin. At the same time, the new method requires significantly lower energy consumption for cooling, as flows can be much lower. The pumps also heat up far from the chip, so they don’t heat it up. And this is one of the key factors of the project, as of course electricity is a factor to consider. In modern data centers, this can be below 10% of the computing power, but on average the figures are up to 30% of all energy consumed.

The approach has been tried on gallium nitride (GaN) chips because these are capable of higher frequencies than silicon chips. With a special technique of making chips, they managed to achieve a heat transfer of 1700 W per square centimeter (chip), which kept the temperature of the chip below 60 ° C. They only needed 0.57 W of power for the pump. In practice, they tested a chip that discharged 176 W, which required flows of about a milliliter per second. In doing so, they properly designed both the chip to delimit the largest heat sources appropriately, as well as the channels to pass the heat sources.